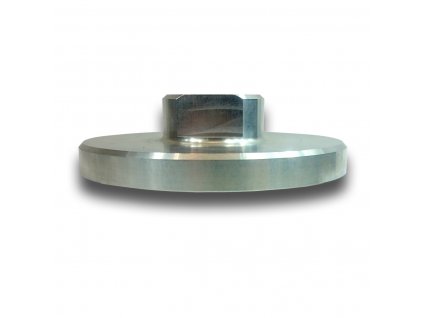

Backers for polishing pads and wheels

Professional Backing Pads for Efficient Grinding and Polishing

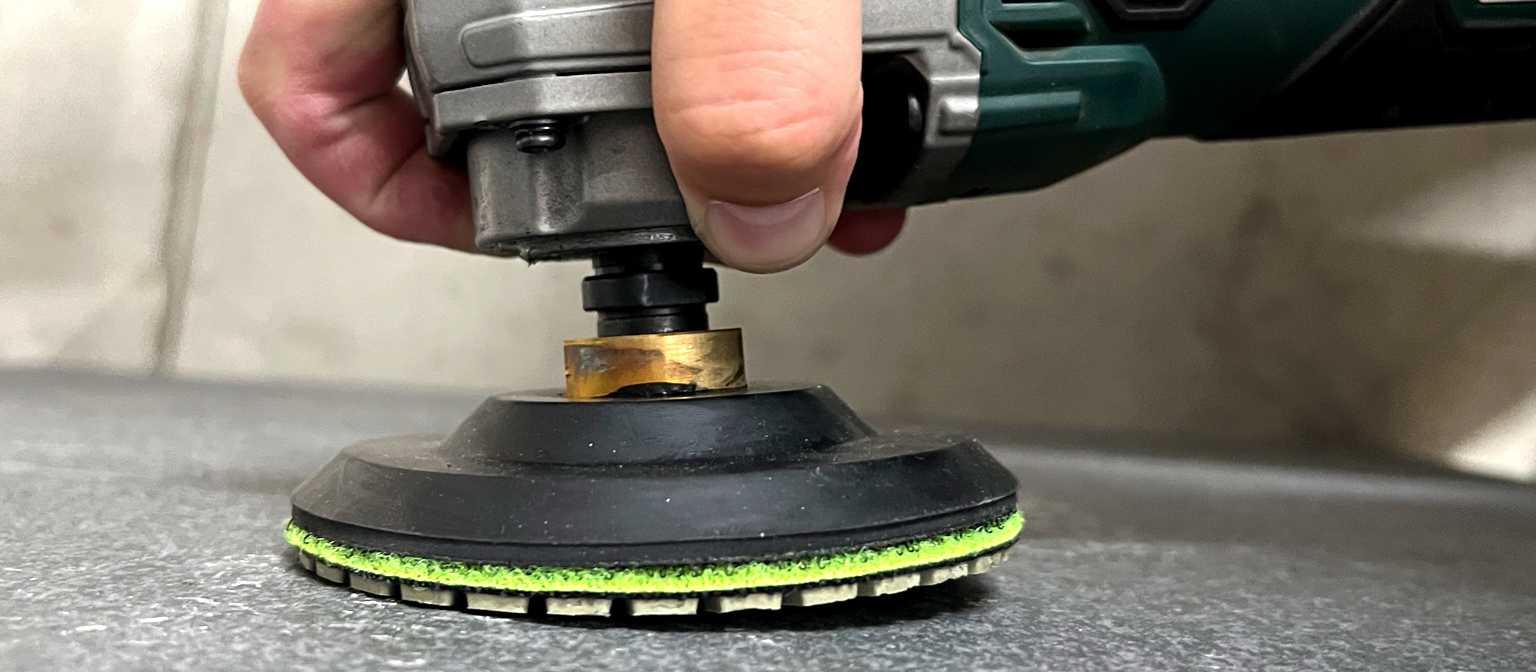

A high-quality backing pad is the key to stability, precision, and safety when working with grinding and polishing discs. Whether you are working with stone, concrete, or metal, choosing the right holder directly affects the final surface quality and the lifespan of your tools. Our range features robust backing pads designed for high-load applications, ensuring perfect power transfer and minimizing vibrations during operation.

Product sorting

List of products

SL/SF/BOSCH

Listing controls

How to Choose the Right Backing Pad?

Choosing the right backing pad should not be underestimated. An incorrectly selected or worn-out head can lead to uneven grinding, material damage, or even injury. When making your decision, focus on four key factors:

Key Selection Parameters:

-

Mounting Type: The most common standard for angle grinders is the M14 thread. For water-cooled machines or specialized grinders, other diameters may be encountered.

-

Pad Hardness: Soft backing pads are ideal for fine polishing and following curved shapes. Choose Hard backing pads for flat surface grinding where high material removal is required.

-

Diameter: Must precisely match the diameter of the disc being used (e.g., 100 mm, 125 mm, 150 mm) to prevent edge flexing.

Hook & Loop (SZ) vs. Snail Lock (SL)

-

Hook & Loop System (SZ): The most universal system. It is ideal for the quick exchange of various polishing pad grits. Caution: Frequent disc swapping wears down the hook and loop fabric. If the fastener does not hold 100%, there is a risk of the disc flying off at high RPMs.

-

Snail Lock System (SL): This bayonet system is better suited for heavy-duty industrial use and automated lines. It provides a firmer, more stable attachment that eliminates the risk of disc shifting. However, if the holder shows signs of "wobbling," immediate replacement is necessary to avoid damaging the machine spindle.

What to Watch Out For?

Safety at work is paramount. The greatest risks are excessive RPMs that exceed the pad's limit and mechanical wear. Therefore, regularly monitor the condition of the hook and loop fabric. If it shows signs of wear, replace it in time or use a completely new backing pad. To extend the life of your tools, we offer several models of replacement hook and loop fasteners, allowing for quick and efficient repair of the contact surface. A worn-out backing pad not only reduces work quality but also increases operator fatigue due to excessive vibrations.