Natural stone, and especially granite, is very popular in construction, sculpture, and of course, stonemasonry due to its properties. A wide range of colors and patterns, along with worldwide availability, make this beautiful and durable mineral both a luxury and an accessible commodity.

Granite, also known internationally by the same name, is characterized by high resistance to both chemical and mechanical influences. This means that properly polished granite is, in most cases, resistant to acidic environments, and its shine is not at risk of degradation.

A Few Basic Tips

There are several types of tools designed for polishing stone without the use of water. Their common feature is that the polishing process can only be applied after thorough surface preparation — after grinding. We covered this topic in the article: "Latest Trends and Techniques in Stone and Concrete Grinding: How to Achieve the Perfect Surface for Your Project"

To achieve the desired result, it is necessary to work precisely with every single grit size offered by the given model of polishing pad.

- Focus on movement so that every part of the surface is processed thoroughly and evenly.

- To prevent overheating, work systematically from side to side across a wider area. Do not linger in one spot or focus on a single point for too long.

- By correctly following the entire procedure, you will achieve a beautiful stone color with a magnificent shine.

- If a mirror-like shine has not appeared, it is necessary to repeat the last two or three grit sizes from the procedure or use a polishing paste, polishing gel, or polishing powder. These products for achieving maximum gloss are applied using a clean felt pad.

Common Mistakes When Polishing Stone Without Water

It is important to mention a very unsuitable, even dangerous combination: using a standard small angle grinder. These machines have speeds ranging from 9,500 to 11,000 RPM. This creates not only unsuitable working conditions for the tool but also, in combination with a worn Velcro backing pad, extremely dangerous situations for your health. The high RPM is too much for the Velcro connection between the grinder's backing pad and the polishing pad to hold. This often leads to the loss of the tool, its damage, and unfortunately, unpleasant injuries. Such a dangerous situation was mentioned in the article "Safety First: How Injuries Occurred from Errors and Poor Tools".

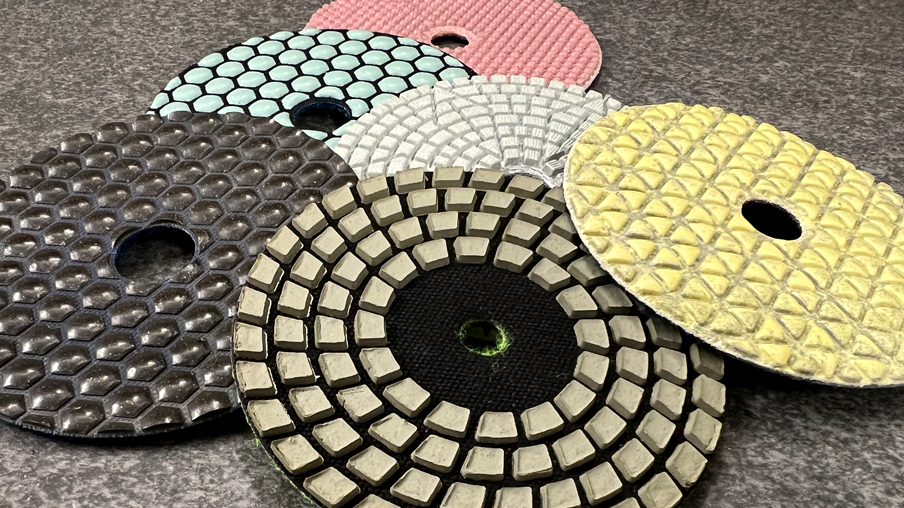

A wide selection of tools for dry stone polishing. The difference is not only in the shape but also in the hardness of the segment, flexibility, and the number of grit steps.

Brief Overview of Tools Suitable for Dry Polishing of Granite

There are several ways to polish natural stone. You can choose from sets ranging from three up to eight steps. What is the difference? You need to consider how high your requirements are for the quality of the result. The difference is most evident when processing colored, dark, or black granites, where multi-step sets are recommended.

- 3-Step - suitable primarily for lighter and colored materials.

- 4-Step - new for 2025. Beautifully polishes even colored and dark materials.

- 5-Step - an extremely popular and time-tested tool. We offer two models for dry polishing: 5-Step for Granite and 5-Step PINK.

- 8-Step - a finely graded set of polishing pads. Grit sizes from #30 up to #Buff are available in diameters from 80 mm to 180 mm. This set guarantees a perfect result even with more demanding materials.

What RPM or Which Machine Should I Use?

An angle grinder with variable speed control is the optimal machine for this job. However, there is no universal or optimally prescribed RPM. It is influenced by the tool diameter, material properties, or the characteristics of the abrasive segment.

It might seem that low RPMs are better regarding overheating. But if you are polishing a flat surface and do not maintain at least a minimal working angle, high temperatures will build up faster than at higher RPMs. This is because while higher speeds may cause heat, the rotation also helps cool the segment better and expels dust.

Most manufacturers recommend a maximum of 6,000 RPM.

Which Backing Pad Should I Choose for My Project?

The choice of backing pad has a significant impact on the proper cooling of the tool, as air is the only cooling medium. You have a choice from a truly large range of backing pads with different diameters. We will help you navigate this selection.

- For polishing narrow stone edges (curbs/bevels), it is better to choose a rigid backing pad. Its hardness maintains and does not deform the shape of the processed surface. The most preferred is a hard plastic or aluminum backing pad. It is important to note that the overhanging surface of the pad is sufficiently cooled by rotation.

- For dry polishing larger areas, a medium-hard rubber backing pad is more suitable. Although it is generally better to use rigid pads on flat surfaces, in this case, high temperatures would build up, which has a negative impact on the tool, the pad, and the overall result. Using a medium-hard rubber backing pad at a slight angle relieves part of the tool and allows for cooling.

- In stonemasonry, the most preferred tool diameter is 100 millimeters. The advantage is good maneuverability and the optimal surface area needed for cooling.

Using a medium-hard rubber backing pad at a slight angle, which helps cooling when polishing flat surfaces.

Can I Add Water Even If the Tool Is Designed for Dry Use?

Polishing stone under water is the optimal and professional procedure. It is the best way to achieve a perfect result. However, this process requires the use of tools primarily designed for stone polishing. Although a stonemason's polisher is very similar to an angle grinder, the main difference is the water supply through the central shaft, i.e., through the center of the tool. Here we get to the heart of the problem.

Even if you poured water from the side under the tool, likely only a minimal or negligible amount of water would reach the working surface between the material and the polishing pad. This is because the rotation of the polishing pad flings the added water away at the perimeter before it can get under the pad.

Regardless of the mentioned issue, using water — even if the polishing pad is intended for dry polishing — is suitable.

What Are the Signs If I Chose the Wrong Procedure?

The working surface of a used, colloquially "open" tool is light-colored. A dark or dark brown discoloration of the pad's working surface (the segment) indicates that overheating and burning of the working surface has occurred. Such a tool needs to be ground down on an abrasive material, such as concrete, firebrick, or sandstone. If the working surface cannot be cleaned, a replacement with a new tool will be necessary.

Although it may not sound very realistic, even the polished surface of the stone can be burned. For example, on black granite, an improper working procedure can cause white-gray scales or brown streaks. Such damage is unfortunately very difficult to repair and will most likely require re-grinding.