Eliminate losses wisely. Sometimes you just need to think about it for a moment, and an idea will strike you.

- By using offcuts from stone slabs and combining them appropriately, you can create tasteful urn graves and monuments—the exact types that are currently becoming more popular.

- Use offcuts to create samples of stone windowsills and establish partnerships with building supply stores. Believe me, people often have no idea that stone is quite an affordable material for their construction.

- Turn offcuts into home or garden accessories such as flower pots, tables, or planters. Alternatively, you can use these products to stylishly enhance your own company's space.

A diamond tool should work the entire time. There is always a way to use it up completely.

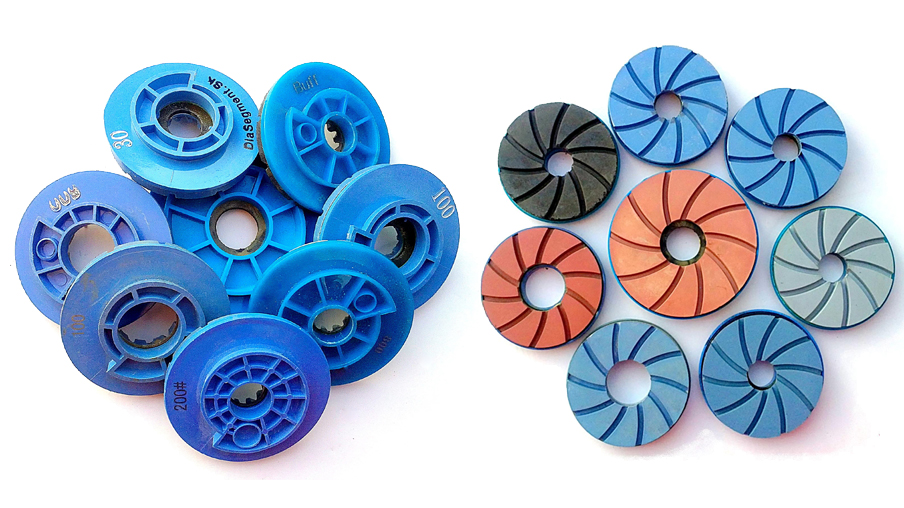

- Unevenly worn Velcro (zip) pads can be cut to a smaller diameter, such as 80 millimeters, and used with a smaller backing pad to continue performing full-value, detailed stonemasonry work.

- Use nearly worn-out polishing pads for beveling stone edges. This is exactly where performance is least critical, yet where tools typically wear out the most.

- I’m sure you know of other ways to save or recycle. Feel free to send them to me in a message, and I’ll be happy to add them.

A TIP from you: stonemason pencils often go missing very quickly, long before they are half-used, and they aren't cheap. Break a new pencil into two or three smaller pieces.

Stonemasonry chemicals also require proper care and optimal storage conditions

- No stonemasonry chemical reacts well to excessively low temperatures or frost. Store sensitive products outside of the masonry season in a stable, at least tempered environment.

- Be careful about storing chemicals in a hot car. High temperatures can change their properties—leading to faster hardening of adhesives, altered density of polyurethanes, inaccurate curing of gold size, or faster expiration.

- Products that cure via evaporation should not have too much air in the container. If there is only a small amount of chemical left in a large container, the remaining material expires faster. We recommend transferring the material to a smaller container or thinning it with an appropriate solvent.

Sometimes tools just seem to disappear in the workshop.

- It can still be used if trimmed to a smaller diameter.

- It can be used for polishing small edges where these tools wear out most, "liquidating them 100%."

- Perhaps an unsuitable backing pad was used.

- We are happy to help and train less experienced employees.

- Is it wise to reveal everything? I’d rather tell you more in person.

- Use one backing pad for each disc; in other words, don't keep peeling and reattaching Velcro discs on a single backing pad. The initial investment is not high, and the efficiency is guaranteed. If craftsmen find it tedious to change threaded backing pads, you can try backing pads with the SL system, which is essentially a quick-release tool attachment.

- You can refurbish older backing pads by replacing the Velcro fabric with new material.

Did the boss go to an exhibition and bring back a bag full of discs?

"If the price of a tool is a technical parameter for you, it's quite likely you won't have room for progress. I assure you that you will be dealing with completely different problems in the workshop."

Let me tell you two more short stories.

- It was around 2012 when I visited a new stonemasonry workshop. I saw that the grinders were working with a mix of discs from unknown manufacturers and suppliers. At that time, I was already carrying a collection of counterfeits so I could demonstrate and show that all tools look remarkably similar, but only one is the original. To gain the client's trust, I let them test the tools. After testing, the grinders immediately responded positively and acknowledged the difference in quality—for the same price they were paying for dodgy tools from resellers. Since then, we are not only business partners, but I dare say, good friends.

- It wasn't that long ago—I won't mention the year for anonymity's sake. In a locally well-known company, I was in a competition with a rival: "whoever arrives first, sells first." I'll admit, I don't like participating in these activities. I respect it if a business owner chooses to work with someone else and I don't waste time persuading them. In this case, however, I picked up the phone and called the owner, saying: "Please, go to the guys in the workshop and ask them a simple question. Ask them which discs they work with best. You have tools there from several manufacturers and several suppliers. Take a good look at the one they point to and find out where you got it from and who made it. Every one of our discs has a logo. Now look at the invoice, see the price you're buying them for, and compare. I know what your guys like working with. I know what they told you. Unfortunately, I know more about them than you do. So why are you buying them expensive yet low-quality tools—knockoffs with no logo, no identity, and no possibility of return or consultation?"

Conclusion

I’ve only mentioned two of many stories. I’ve shared several interesting insights I've gained during my career.

However, I know that trust isn't easily earned. It can't be bought, it can't be acquired cheaply, and it certainly can't be bought in some Chinese warehouse. The most expensive value in our lives is time, and in these stories, it plays a vital role. Those who realize this are two steps ahead of everyone else.

Pavol Šáray

CEO & Technical Expert DiaSegment

I spend most of my time in the field with customers, searching for the best solutions for their specific tasks directly at construction sites or in stonemasonry workshops. These trips are my greatest inspiration—I process practical feedback into technical articles to help you navigate the industry. Since I am often in full work mode, you might not reach me immediately, but I will be happy to give your questions my full attention.

✉️ E-mail: diamantovenastroje.cz@gmail.com

📞 Mobile: +421 903 528 039

Available on business days 8:00 AM – 4:00 PM.

If I don't answer, please send me an SMS or WhatsApp, and I will get back to you.