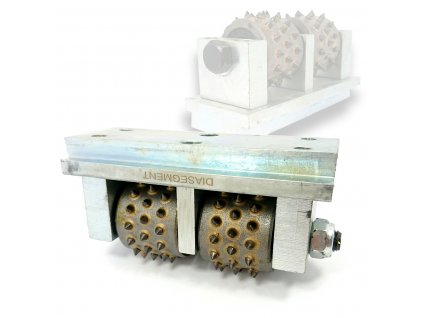

Bush hammer for stone

Bush Hammering: The Ultimate Surface for Stone and Concrete

Give your projects a unique look and enhanced safety. Bush hammering (stocking) is a precision surface treatment technique that creates an aesthetic granular texture with excellent anti-slip properties. Whether you are working with natural stone or following the modern trend of bush-hammered architectural concrete, our range offers professional bush hammering tools that guarantee uniform results and long-lasting performance.

Technical advice and experience from Pavol Saray, founder of DiaSegment:

🔴Bush-hammering in practice: How to transform an ordinary surface into a modern feature?

Product sorting

List of products

Why Choose Bush Hammering for Your Projects?

Bush hammering, traditionally a stonemason's craft, has undergone a major evolution in recent years. While it was once primarily used for renovating historical monuments and natural stone staircases, today it has become a dominant element of modern architecture.

Bush-Hammered Concrete – A Modern Architectural Trend

There is a growing demand for treating concrete surfaces in both exteriors and interiors. Bush-hammered concrete effectively masks minor casting imperfections and gives monolithic surfaces a luxurious, natural character reminiscent of granite.

Main Advantages of Bush-Hammered Surfaces:

-

Maximum Safety: Creates a certified slip-resistant surface ideal for walkways, ramps, and pool areas.

-

Aesthetic Value: Reveals the internal aggregate structure, adding depth and texture to the surface.

-

Durability: Treated surfaces better withstand weathering and mechanical wear and tear.

Professional Equipment for Every Surface

In our shop at diamantovykotuc.sk, you will find specialized bush hammering rollers and plates fitted with tungsten carbide (widia) tips, designed for heavy-duty use. Our tools ensure:

-

Consistent texture depth without unwanted grooves.

-

High work efficiency thanks to optimized tip geometry.

-

Universal compatibility with hand grinders and large floor-grinding machines.

Whether you are executing fine stonemasonry or large-scale concrete flooring, choosing the right grit and tool size is the key to success. If you are unsure about your choice, our technical advisors are ready to help you find the ideal solution for your specific material.