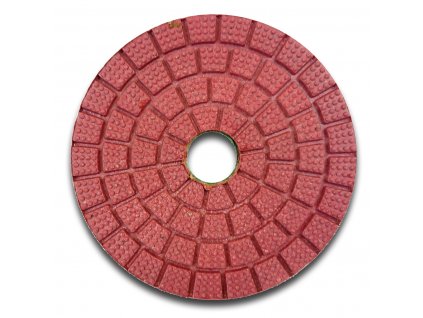

Flexible pads for wet polishing of stone

Professional Flexible Polishing Pads for Wet Stone Polishing

Achieve a perfect mirror finish and smooth surface with our range of flexible polishing pads for wet use. These tools are specifically engineered for the precise processing of natural and engineered stone, such as granite, marble, and concrete. Thanks to a high concentration of diamond grit and a premium resin bond, they guarantee long service life and exceptional work efficiency under water cooling. Choose from a wide range of grits, from coarse grinding to final high-gloss polishing.

Expert articles from our technician:

🔴Polishing stone like a pro. Procedures, tools and tools you need

🔴How to polish terrazzo, concrete or exposed concrete: The complete guide, tips and tricks

🔴10 basic steps for successful marble polishing at home

🔴Where is money lost in a stonemason's workshop? Part One - Saving in the Wrong Place

Product sorting

List of products

Why Choose Diamond Segments for Wet Processing?

Wet polishing is the most effective way to eliminate dust during work while preventing the overheating of both the material and the tool itself. Our soft polishing pads are developed to follow the contours of the processed surface, making them the ideal choice for polishing edges, bevels, and curved profiles.

Main Advantages of Our Polishing Tools:

-

High Flexibility: The pads adapt perfectly to surface irregularities, reducing the risk of unwanted scratches or gouges.

-

Color Coding: Each grit size is clearly distinguished by color, making orientation easier and speeding up the tool change process during work.

-

Universal Attachment: The hook-and-loop system ensures quick and secure mounting onto the backer pads of most hand grinders with variable speed control.

-

Surface Clarity: The use of water flushes out ground material, preventing segment clogging and ensuring a crystal-clear, streak-free result.

Recommended Procedure: To achieve a mirror-like shine, we recommend proceeding systematically from the coarsest grit (usually 50) to the finest (3000 or Final Buff). When working with water, maintain optimal pressure and adhere to the recommended RPM to maximize the lifespan of the diamond layer.