Stone satin finishing

Professional Tools for Stone Texturing and Antique Finishing

Add unique character and depth to natural stone surfaces. Our range of stone brushing tools is specifically designed for craftsmen seeking to achieve the popular "leathered" or satin finish. These tools allow for precise enhancement of the natural texture of materials such as granite, marble, and sandstone, creating a visually and tactually appealing relief with high added value.

Product sorting

List of products

Listing controls

Brushing Technology: From Rugged Texture to Silky Sheen

Stone brushing is a sophisticated process that mechanically transforms a smooth surface into a textured one. Unlike flat grinding, brushes follow the varying hardness of the minerals within the stone’s structure—softer components recede while harder minerals remain prominent, creating a natural, organic appearance.

Applications for Our Brushing Tools:

-

Creating an Antique Effect: Achieve the look of aged, time-worn stone, a top trend in high-end interior design.

-

Leathered Finish: An ideal choice for kitchen countertops and flooring where a matte surface with a velvety texture is desired.

-

Enhanced Safety: Brushing creates a natural anti-slip surface, which is crucial for exterior stairs and terraces without compromising the material’s aesthetic qualities.

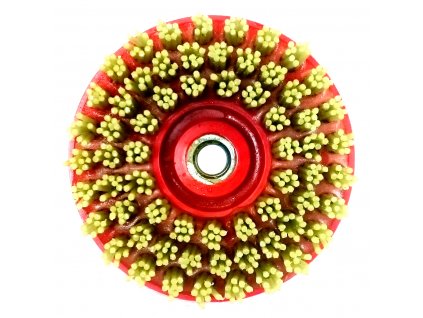

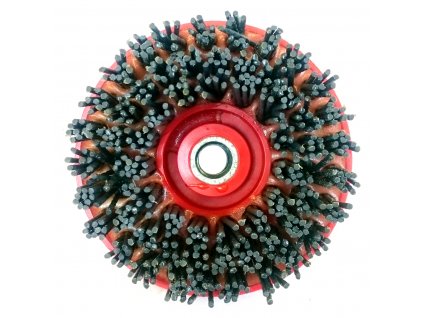

Technical Specifications and Operational Guidelines The quality of the final finish depends on the composition of the tool's filaments. Our product range includes brushes where the bristles are embedded with diamond or carbide abrasive grits. Diamond grits are engineered for hard materials (granite and engineered stone), while carbide (SiC) grits are ideal for softer stones (marble, limestone).

Important Notice: For optimal results and tool longevity, it is highly recommended to perform brushing using a wet process. Dry brushing generates excessive friction, which poses a risk of overheating, deformation, or permanent melting of the abrasive filaments, potentially damaging both the tool and the stone surface.

Wide Compatibility for Every Workshop: We have tailored our selection to meet the needs of both small workshops and large-scale industrial operations:

-

For Handheld Machines: Brushes with a standard M14 thread for easy mounting on angle grinders.

-

For Industrial Machinery: Specialized brushes with Fickert attachments and large-format discs with a 250 mm diameter for automated lines and radial arm polishers.

To achieve a flawless result, we recommend a sequential process starting from the coarsest grits to define the relief, moving to the finest grits to seal the surface and provide the desired satin luster.