Superglue 125g and activator 400ml - Akfix 705

125g | 400ml

| Category: | Sealants and adhesives |

|---|---|

| Weight: | 0.45 kg |

| Profession: | stone mason, tiler |

Akfix 705: Professional Assistant for Tilers and Stonemasons (125 g + 400 ml)

Akfix 705 is a high-performance cyanoacrylate adhesive and activator kit that has become the industry standard for processing natural stone, porcelain stoneware (gres), and large-format tiles. Thanks to its lightning-fast reaction, it is invaluable especially for installations requiring maximum precision without the risk of material shifting.

Key Applications in Stone Fabrication

-

Quick Fixation Before Final Bonding In stonemasonry, Akfix 705 is often used as a "helping hand" for the immediate fixation of parts. For demanding joints, such as massive stair treads, kitchen countertops, or fireplaces, it is used in combination with two-component adhesives (e.g., epoxy or epoxy-acrylate fillers).

-

Procedure: Apply a slow-curing epoxy to part of the surface for extreme structural strength, and apply Akfix 705 with the activator to several strategic points. The latter will immediately "hold" the joint in the exact position, allowing the epoxy to cure undisturbed (often taking several hours).

-

-

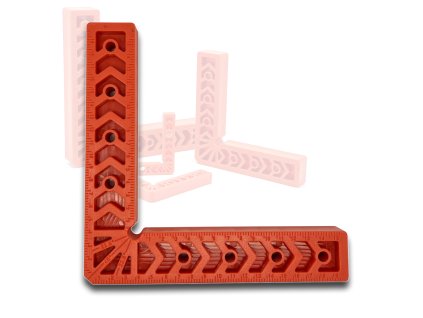

Working with Plastic Brackets When creating 45° joints (so-called "miter" or "jolly" edges), Akfix 705 is used to attach auxiliary plastic brackets. These brackets temporarily maintain the geometry of the joint from the outside while a reinforcing mesh or structural adhesive is applied from the inside. Once the main joint has cured, the plastic brackets are simply removed.

-

Installation of Finishing and Skirting Boards Enables immediate attachment of boards to the substrate without the need for mechanical support or taping.

Advantages for Professionals

-

Replaces Clamps: Allows for faster workflow without the need for complex clamping of parts.

-

Gel Consistency: The adhesive does not sag on vertical edges and stays exactly where you apply it.

-

Transparency: Creates a clean, clear joint that does not show through light-colored stone or ceramics.

-

High Chemical Compatibility: Works safely with subsequently applied epoxy and polyester resins.

Work Procedure for Stone and Tile Fixation

-

Preparation and Cleaning: Surfaces must be completely free of cutting dust and grease. When working with stone, we recommend vacuuming the surface and wiping it with technical alcohol (denatured alcohol).

-

Activator Application: Spray the activator onto one side of the joint or onto the plastic fixation bracket. Allow it to flash off for 5 seconds.

-

Spot Application of Adhesive: If using Akfix 705 as an auxiliary fixation for epoxy, apply it in spots where the main structural adhesive has not been applied. If bonding plastic brackets, apply the adhesive directly onto them.

-

Joining and Alignment: Position the part precisely. Upon firm pressure against the activated surface, curing occurs within 5 to 10 seconds.

-

Final Phase: Once Akfix 705 has fixed the parts, you can carefully handle the assembly or continue applying the main layer of epoxy/epoxy-acrylate adhesive to the remaining parts of the joint.

Warning: When using on highly porous materials or extremely light marble, we recommend performing a test on a scrap piece beforehand to check for unwanted edge staining (the so-called "halo effect").

Be the first who will post an article to this item!